Pipe Stopper Use & Safety Tips

WARNING! Not taking notice of this information may cause damage, injury or death!

All of the 0.5 bar stoppers that are capable of a water test that we distribute require bracing when fitted. The reason for this is whilst the stopper will make a seal to hold 0.5 bar the friction between the stopper and the pipe can not be relied upon to hold it into place.

The eyelets on the ends of the stoppers are only for location and are not to be used as the form of bracing. The brace is simply made and should be as in figures 1 and 2.

Figure 1:

For By-Pass Fluming or Test Ends

- Centre of bag

- Inflatable bag envelope

Figure 2:

For Blank Stoppers

- Outside wall with pipe opening

Prior to installing, ensure that pipes are checked for any sharp protrusions, stones and debris that may puncture the stopper upon inflation. All 0.5 bar stoppers must have a 10 metre inflation hose supplied with them so as to ensure operative safety when installing, inflation should be done remotely. Air pressure should be checked in accordance with the operating instructions.

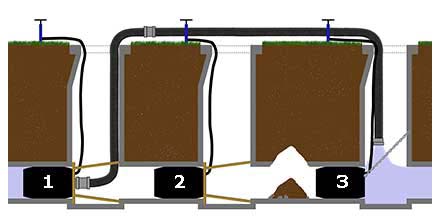

The 0.5 bar stoppers can be used for fluming, blanking, water tests to 0.5 bar and leak location, a sample of how this can be done is shown in figure 3.

Figure 3:

- By-pass stopper connected to a pump

- Blank stopper braced in case the by-pass fails

- Blank stopper to ensure the over pumped flow does not flood the workforce

All pipe stoppers are supplied with full instructions, please read them, they are for your safety.